Counterfeit drugs or medicines pose a risk to consumers and pharma businesses alike. Beyond the health and safety risk to consumers, it could be deadly at its most severe. Indeed, The WHO (World Health Organization) estimates that there are over 1 million deaths worldwide as a result of counterfeit or substandard drugs and medicines.

There are also questions of cost and the risk to a pharma company’s reputation. A 2020 report by Statista estimated that counterfeit drugs raised 200 billion dollars in revenue which by today’s estimations can only have increased. This means that 200 billion dollars have been lost from the legitimate pharma market as a result. Furthermore, the report elaborated that such a financial burden could prevent up to 13 new drugs from coming to market every year, which could have further negative impacts on consumers who need innovations and products.

An additional report by the Partnership for Safe Medicines highlighted that in the U.S alone they estimate that up to 19 million consumers are purchasing drugs outside of a legitimate and safe drug supply and that since 2012 smugglers have been caught selling 63 types of illegitimate drugs to 3000 dispensers (doctors, pharmacies, clinics and hospitals) nationwide.

Internationally, Pfizer confirmed that there are now counterfeited versions of 80 types of drugs across 110 countries.

The statistics look bleak, and it may seem impossible to change the forecast. However by creating barriers and focusing on innovation, pharmaceutical companies stand a chance of reducing those figures and protecting themselves and their consumers from counterfeit drugs.

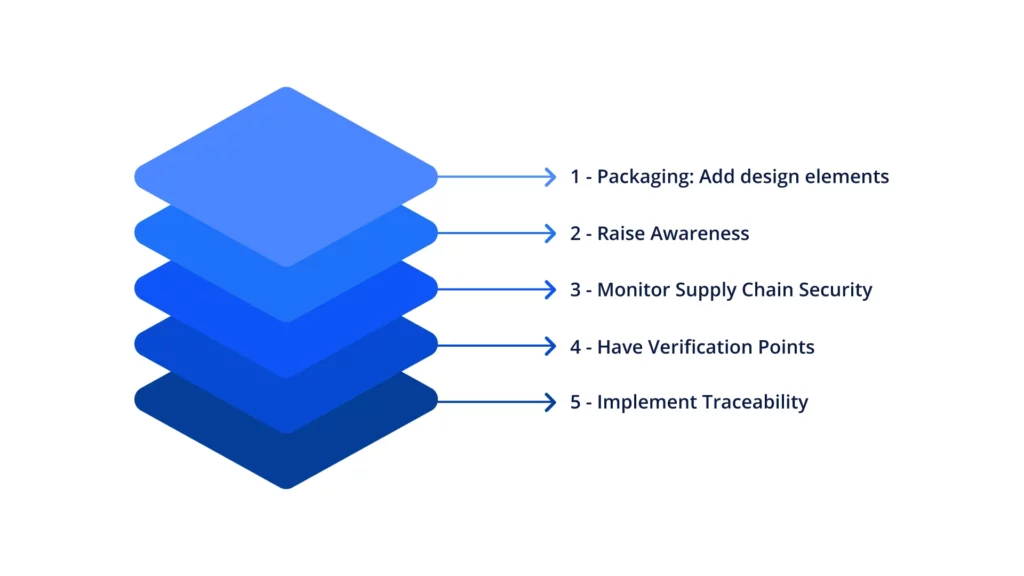

We have outlined five strategies:

- Packaging: Add design elements

- Raise Awareness

- Monitor Supply Chain Security

- Have Verification Points

- Implement Traceability

1. Packaging: Add certain design elements to your packaging to make counterfeiting more difficult.

Serialization on packaging is not only becoming an FDA requirement but also helps prevent counterfeit drugs from entering the supply chain. The GS1 DataMatrix for example allows a product to be uniquely identified on its packaging from manufacturing through to distribution. There are also barcodes and RFID tags which also help in verifying the uniqueness of the product and packaging. These unique product identifiers make it harder for counterfeiters to mimic and allow a well-fitted traceability system to track the product throughout the supply chain, preventing theft. Holographs and other additional detection layers can also add to the security of a given product.

The more information that can be relayed and stored through unique product identifiers the safer the consumer will be, with GS1 DataMatrix reducing medication errors by 50% and adverse drugs by up to 75% in the hospital environment.

TrackTraceRX has developed a solution for smart packaging: RapidRX. RapidRX is a solution for printing barcodes and unique product identifiers such as GS1 DataMatrix onto a product’s packaging or labels without needing to use special inks or other complex printing processes. These unique identifiers are imperceptible to the naked eye maintaining the integrity of a given product whilst still providing transparent product information adhering to the strictest international quality standards. This allows the consumer to confirm authenticity and by extension; the safety of a given product. TrackTraceRX is also an associate member of GS1. GS1 is a global trendsetter in this field and has a variety of webinars, conferences, and online materials about drugs in healthcare systems that can easily be accessed.

2. Raise Awareness and Work with regulatory agencies.

Several regulatory organizations have programs in place to prevent counterfeiting. Agencies such as the Food and Drug Administration (FDA) in the U.S., and the World Health Organisation (WHO) need participating pharma companies and countries to collaborate, raise issues, and improve initiatives; such as stricter enforcement regimes for culprits and the latest guidelines and developments for companies to follow in line with prevention efforts. The FDA also has a counterfeit alert network which notifies members of their network if counterfeit medicine has been reported. This helps to inform and make the healthcare community aware including consumers and professionals in the area.

Regulatory agencies can also issue useful guidance such as the medical supply chain toolkit from the FDA, created to help pharma companies navigate through the upcoming DSCSA requirements and keep their supply chains safer and more secure. You can read about it in further detail here.

Furthermore, legitimate drugs can only be purchased from National Association Boards of Pharmacy (NABP) certified pharmacies. The NABP also has a compounding pharmacy information-sharing project with the FDA. Therefore it is important to participate and work with regulatory agencies to improve the system as a whole and alert the national and international network of high-risk counterfeits.

3. Have a dedicated individual or group to monitor supply chain security.

Security is important and if security is not in your general employees’ skill set, it might be worth investing in a dedicated security body that specializes in the field. This can be contracted externally from specialist companies. Beyond monitoring and improving the security of the supply chain, theft prevention should also be high on the agenda. Information sharing and communication within the organization are paramount as different aspects of product safety need preventative counterfeiting measures. This is due to the many different ways that a product can be tampered with.

4. Supply chain integrity: have verification points at different links in the chain

Because there are many different links within a pharmaceutical drug supply chain it is important to have salient and well-established product identity, purity, and quality as it passes through the chain. Some key links in the chain are where raw materials are received at a facility after these are processed; and dosed into vials for example, as well as when units are packed into cartons and pallets and also when these are received at distribution centers. These links are particularly vulnerable to tampering and counterfeiting. Therefore verification of the unique product identifiers is crucial; such as customs checks and hard copies of accompanying documentation. It is important that the integrity of the supply chain is maintained and a pharmaceutical company should know their supply source and have continuous dialogue with supply chain professionals including quality control where applicable at every stage of the process. This will ensure improved safety and control over drugs and medicines.

5. Innovate your company by implementing a secure supply chain traceability system

To have effective supply chain security, multiple layers of protection are fundamental. Perhaps the most important of these is a robust, user-friendly, seamless, and secure traceability system. TrackTraceRx is one such provider. A traceability system is a solid foundation for effective execution. If there is a problem with a given drug, or it is reported as counterfeit, tampered with, or generally unsafe, traceability allows pharma companies to respond quickly by:

- Acting quickly with product transparency

- Identifying the scope of the problem

- Locating counterfeit drugs quickly

- Locating affected lots and impacted locations/customers

- Initiating the recall of the product with the surrounding recall logistics with ease

- Identifying the source of the problem.

All of the above helps to maintain market and consumer confidence.

A traceability provider will also help pharma companies meet the DSCSA 2023 interoperability requirements.

TrackTraceRX offers solutions that are DSCSA compliant by implementing an interoperable electronic system that tracks prescription drug sales and dispensing. Don’t hesitate to contact our team of experts if you require more information or advice.

{{cta(‘c53b7ee2-ee57-447b-89ef-0e1eddd533c0’)}}